About Armour Technocast

Armour Technocast is a leading manufacturer of investment castings by lost wax method and able to supply components in various conditions like raw, finished, assembled or as per customer’s demand.

The company has earned reputation by providing castings to the various industries according to their stand requirement and also in customized size, wide range of materials.

Our experienced professionals are involved for providing a superior product value, rather than just a low unit cost with assured quality within time frame.

We are expert to provide Raw Casting and Machined Components with Highly Accurate CNC, VMC, Rotary and Milling Machines with CMM Facility.

We are providing castings with NDT, RT, TENSILE, HARDNESS, FERRITE, MICROSTRUCTURE, MP, DP Testing as well.

We employ dimensional inspection, chemical spectro analysis, physical properties testing and non-destructive testing techniques to guarantee that every casting meets customer’s intended dimensional accuracy, design tolerance and structural integrity requirements.

Mission

To produce net 0 (zero) defect casting and make casting in all critical segments and extend the boundary of human in investment casting manufacturing.

Vision

To manufacture world class casting to regional and global clients and mark the name of armour technocast at global level as précised technocrats and precision casting manufacturer form India

QUALITY POLICY

Strong quality assurance structure, a series of inspection activities and modern testing equipment facilitate our qualified professionals to guarantee for consistent quality of casting. We employ dimensional inspection, chemical Spectro analysis, physical properties testing and non-destructive testing techniques to guarantee that every casting meets customer’s intended dimensional accuracy, design tolerance and structural integrity requirements.

Process

- The Dies (Patterns/Tools) are manufactured using NX Software (even for 3d modeling for customers satisfaction).

- ARMOUR TECHNOCAST also provides technical support to its customers to develop cost saving and more efficient products.

- Injection and production of wax pattern from Dies (Patterns/tools). All Wax patterns are 100% dimensionally checked.

- The Wax pattern after forming the tree or cluster undergoes the ceramic coating process. This process is done in temperature and Humidity controlled rooms, so that best dimensional accuracy and excellent surface finish is achieved.

- After completing the coating process, the wax is removed by de-waxing process, which is done by putting the ceramic mold in the hot bath of wax.

- The Ceramic molds are baked at temperature ranging from 900°C to 1150°C depending on the geometry and size of the casting. The molten metal is then poured in the baked ceramic molds.

- The casting then undergoes fettling and finishing process such as Gate Cutting, Gate Machining / grinding, Sand Blasting, Shot Blasting, Leaching, Deburring etc.

- The casting then undergo the Heat Treatment as Per the material specifications.

- Heat Treatment graphs are cycles are recorded and documented.

- All castings are subject to 100% visual inspection as per MSS SP-55.

- All critical dimensions are 100% inspected before packing and shipment.

- ARMOUR TECHNOCAST can also supply castings in machined condition.

- Castings can be also supplied with various type of finishing such as passivation, Electro-polishing, Blackening, powder coating, shot blasted, Glass bead blasted.

Quality assurance

Chemical Analysis:

In house spectrometer with 5 channels capable of testing Fe, Ni, Cu, Al based materials and also Nitrogen content.

All heats poured are tested on-line on Spectrometer.

All the scrap used are also tested before using.

Specimens are stored for particular period.

Physical Testing:

In house Universal Testing Machine.

In house Hardness Testing Machine.

In house Impact test Machine.

In house metallurgical microscope.

TUV NORD ISO 9001:2015

TUV NORD AD 2000-Merkblatt W 0

TUV NORD PED 2014/68/EU

Production capabilities

Manufacturing Process

- Investment Casting by lost wax method

- Precision Machining and Buffing

- Component Assembly as per Customer Requirement

Component Handling Capacity by

- Size: 550 mm (L) X 530 mm (W) X 420 mm (H)

- Pouring Wall Thickness: Minimum 0.8mm to Customer demand

- Weight: 0.006 kg to 160 kg per piece.

- Surface Finish : Ra3 to Ra6

Materials Offered

We are Providing Various grades according to ASTM, AISI, DIN, EN, GOST, JIS and other international standards. Flexibility of selection from Austenitic Stainless Steel, Carbon Steel, Low Alloy Steel, Martensitic Stainless Steel, Duplex steel, Precipitation Hardened Steel, Ductile Iron, Cast iron, Aluminium Alloy, Copper Alloys and any specific requirements.

Production Capacity

1500 MT per annum.

Supply condition

Raw, finished, assembled or as per customer’s demand.

Services

- Machining

- Special Heat Treatment

- Surface Treatment

- Assembly

- Mechanical Property

- Chemical Property

- Microstructure

- MP

- PMI

- DP

- Ferrite Testing

- Radiography testing

Our Portfolio

Industries we serve

VALVE INDUSTRY

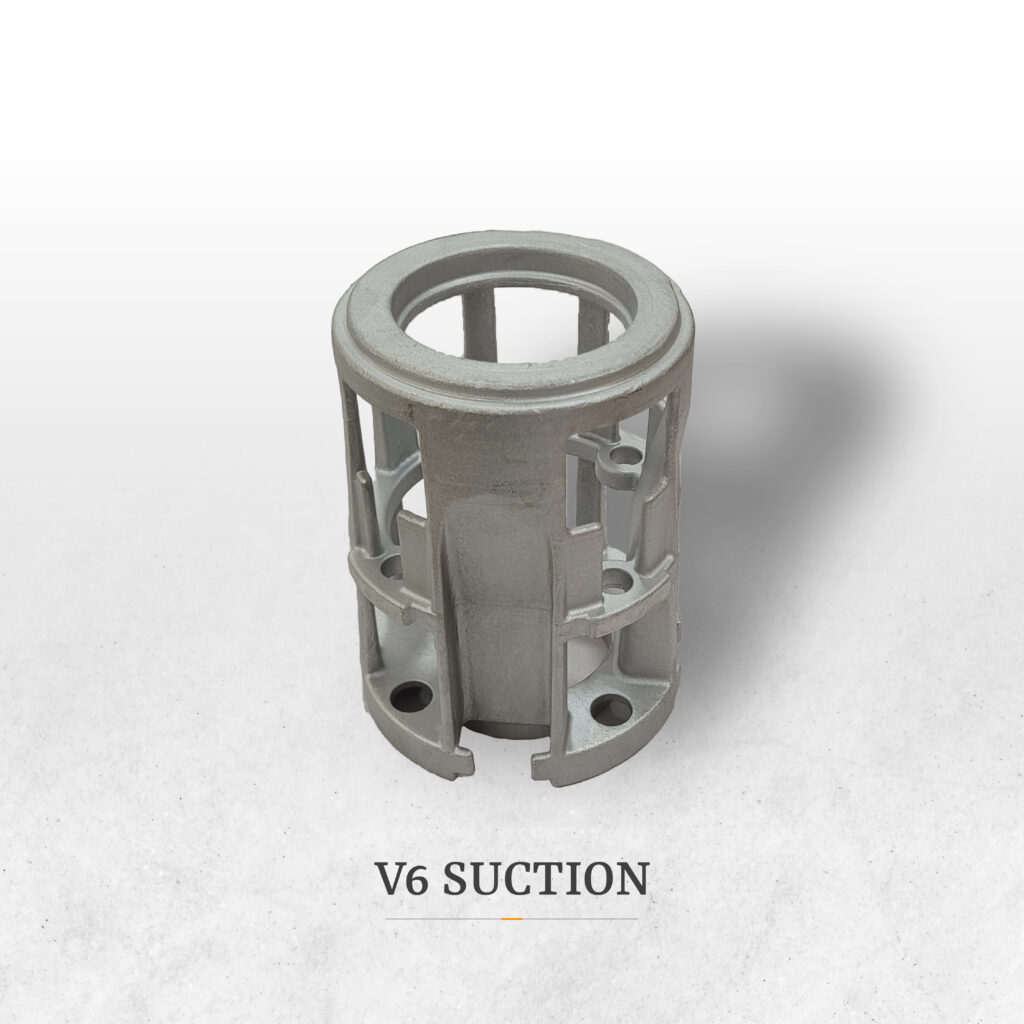

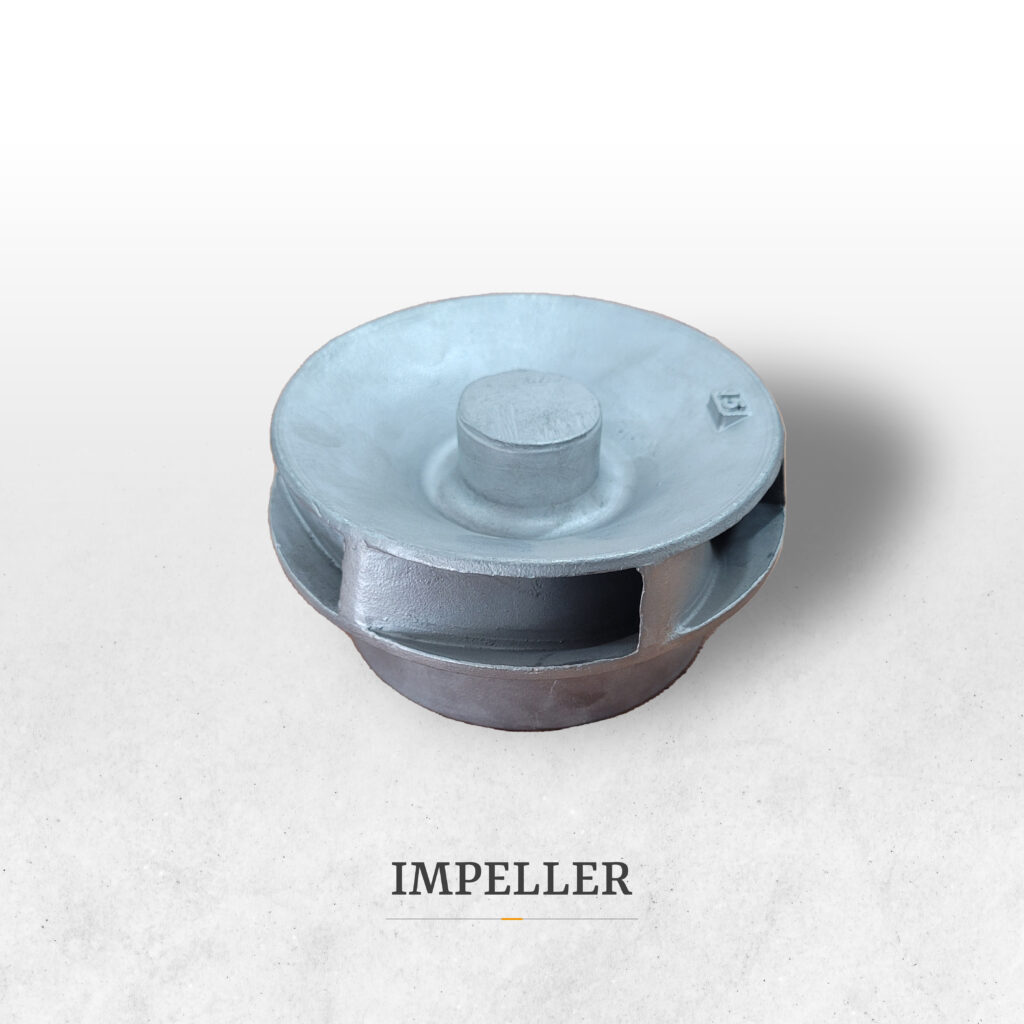

PUMP INDUSTRY

GENERAL ENGINEERING

AUTOMOTIVE INDUSTRY

AGRICULTURE INDUSTRY

MINING INDUSTRY

HARDWARE INDUSTRY

TEXTILE INDUSTRY

Facilities

Inspection & Testing Equipments

| No | Description | Make | Qty |

|---|---|---|---|

| 1 | Optical Emission Spectrometer | ARL | 1 |

| 2 | Utm (Digital) | Meta | 1 |

| 3 | Electronic Extensometer | Meta | 1 |

| 4 | Computerize Hardness Tester | Meta | 1 |

| 5 | Impact Testing Machine | Meta | 1 |

| 6 | Surface Plate | Luthra | 1 |

| 7 | Digital Vernier | Mitutoyo | 3 |

| 8 | Digital Height Gauge | Mitutoyo | 1 |

| 9 | Combination Set | Yamayo | 1 |

Future Plans

Armour technocast will form a group of companies specilised in casting and foundry development With future goals of suppling 2400 mt of investment casting to global and domestic customers. And even establishing an 2 new casting division for sand casting and alluminium casting to mach the global demand .

Contact Us

You are welcome to visit our Company. For orders and sample requests, please call us or send us an email.

Location

Survey No.47/1 Bhunava, Gondal, Rajkot – 360311

Gujarat – India.

+91 88666 05706

+91 70161 93781

info@armourtechnocast.com

armourtechnocast@gmail.com

Business Hours

Thursday to Tuesday – 9am to 5pm

Wednesday – Off

Note: All Commercial Holidays are Applicable

24 x 7 Live Customer Support Available